Applications

Assembly

Autoquip is your partner for the design and manufacturing of lift equipment to improve your assembly production. Our lifting solutions are developed on the basis of your specifications whether that is to have materials, equipment, or workers available when and where they are needed to complete the assembly process.

Experience & Expertise

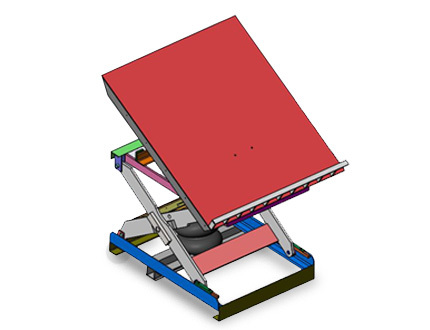

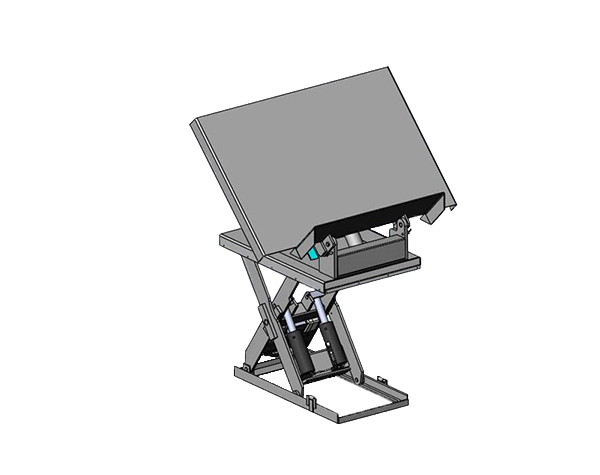

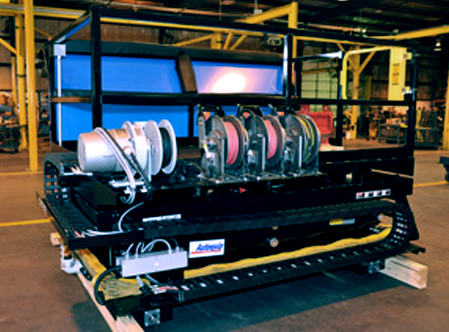

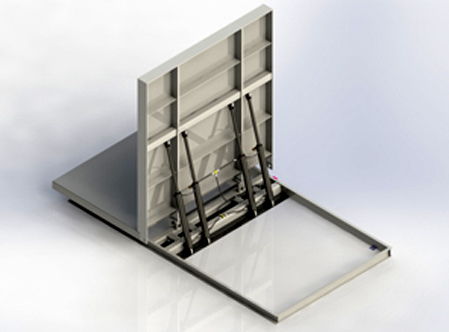

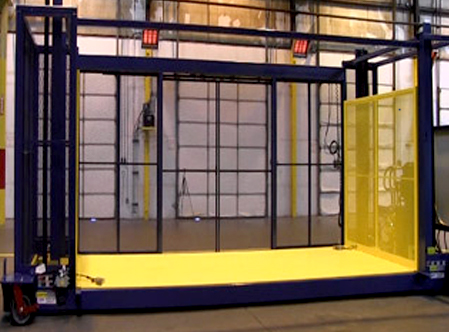

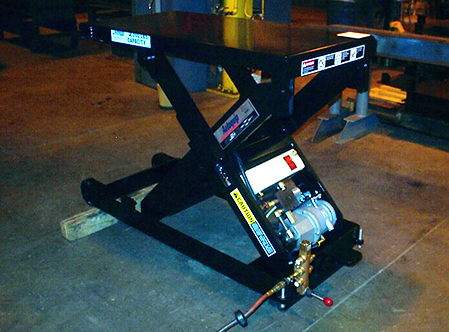

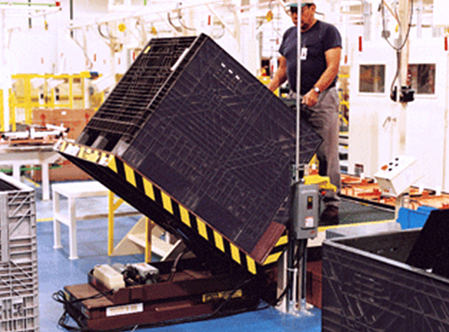

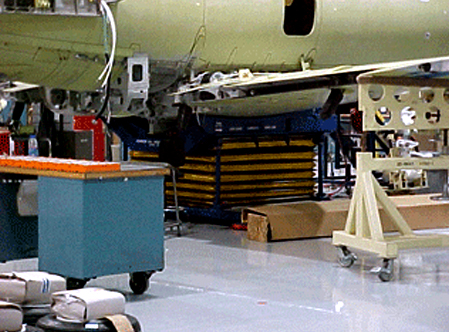

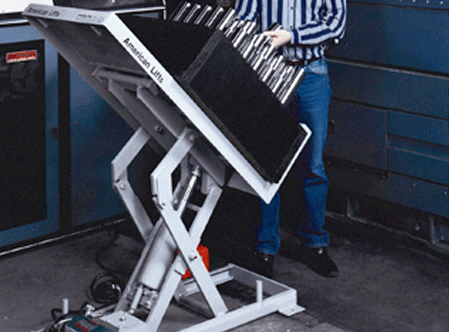

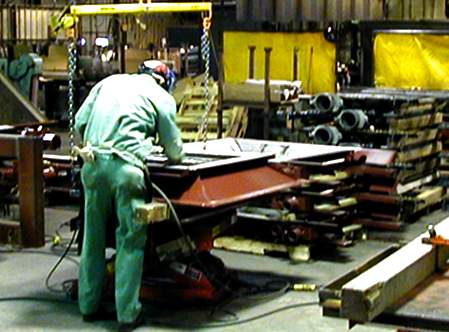

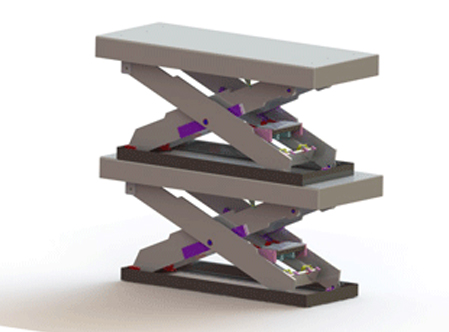

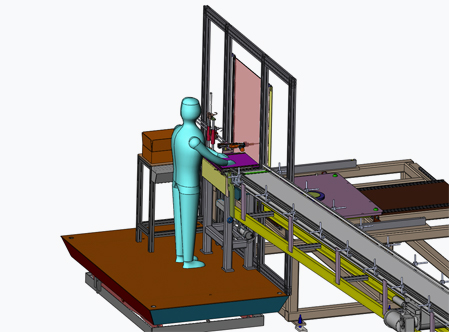

Lifting and handling solutions Autoquip designed and manufactured for assembly applications.

Portable hydraulic scissor lifts work in tandem to raise and lower the entire fuselage of a business jet to provide variable working heights during the assembly process.

Stacked scissor lifts, or single ram platform lifts, ergonomically positions a jet engine by lowering it into a recessed pit while workers stand on and work from the adjacent, fixed floor level.

A system of multiple scissor tables are used to raise varying truck cab models off the floor-mounted drag-chain conveyor line to complete the assembly process and drive the cabs to the shipping area.

Scissor lift with a gravity or powered conveyor are used to transfer and position products during the assembly and packaging process.

Fixed and portable scissor lifts provide assembly personnel access to the sides and top of a modular home during assembly, painting, and inspection.

Hydraulic or pneumatic scissor tables are used to ergonomically position cabinet components and assemblies with or without conveyors.

Articulating Bullet Lift