Applications

Hazardous Environment

In order for Autoquip to develop a design specification for an explosion-proof application, clear direction must be given of the specific classification in the operating atmosphere. In North America, hazardous locations fall into various classifications based on three criteria: class, division, and group. Autoquip will recommend the most accurate lift solution that includes proper specification and design.

Experience & Expertise

Lifting and handling solutions Autoquip designed and manufactured for explosion-proof applications include:

A hydraulic vertical reciprocating conveyor lift, with non-sparking rollers and non-carbon steel carriage guide beam inserts, can transfer live munitions from storage level to loading dock level.

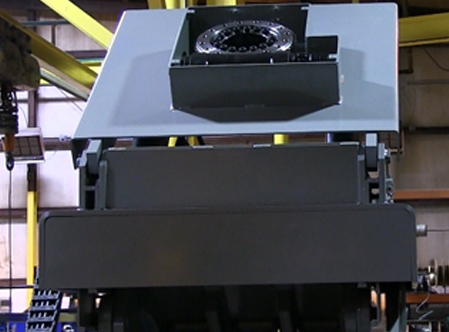

A High travel hydraulic scissor lifts with non-sparking scissor rollers and intrinsically safe electrical controls.

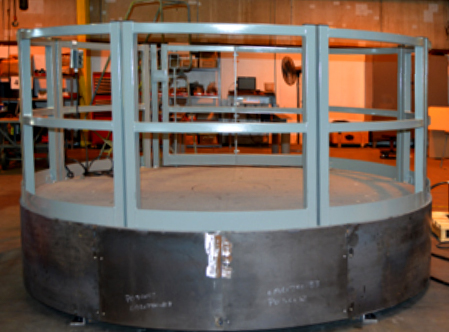

These are hydraulic scissor tables with handrails and gates that are operated using shop air supply to air up a motor/hydraulic pump.

A hydraulic scissor table with an air footswitch operator controls and an air-operated power unit is used to build up pallets of bagged product.

Hydraulic lift tables with air controls are used as personnel work platforms in explosion-proof areas to perform engine maintenance.