Applications

Sheet Handling

Autoquip custom lifts have been designed and manufactured in America's heartland for over 70 years and have grown to become the top choice of customers who demand the very best in rugged, versatile, and safe sheet handling equipment. Autoquip has designed custom solutions for the indexing, feeding, transporting, and lifting of sheets and flats for a wide variety of applications.

Experience & Expertise

Lifting and handling solutions Autoquip designed and manufactured for sheet handling applications include:

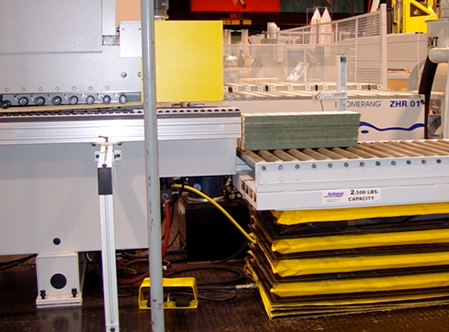

Hydraulic scissor tables, equipped with photo-electric sensors, are placed at either in-feed or out-feed conveyor positions adjacent to process machinery in order to automatically index up or down as layers of material are removed or added to a conveyed pallet.

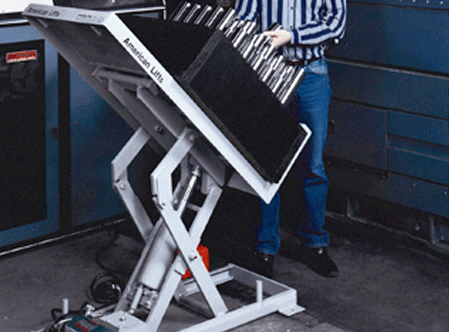

Foot-operated lifts, installed just upstream of powered planers, manually adjusts the elevation of the top layer of lumber and plywood for ease of pulling and aligning the pieces into the planer.

Scissor tables are used to index down automatically as layers of cardboard are dropped onto the lift on the out-feed side of a cutter.

A special non-intrusive tilter is used to rotate a stack of cardboard standing on edge to center the load and even up all edges before banding/bundling.

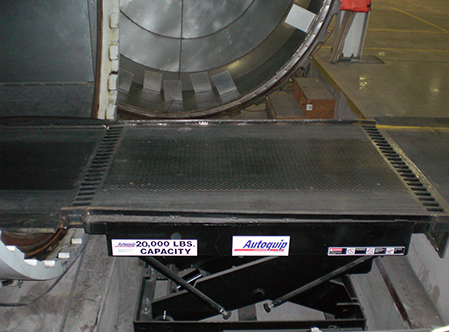

A high-capacity scissor lift on a traversing base has a large powered turntable for receiving, rotating, delivering/traversing, and raising sheets of metal to feed a blanking machine.