Industries

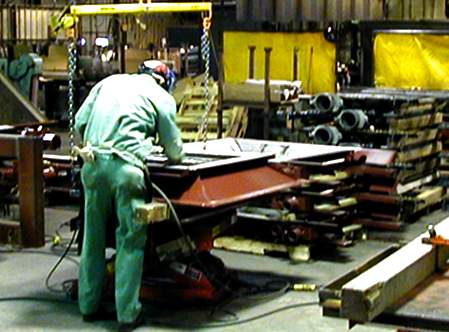

Metal Working

Autoquip respects the demands and rigors of the metal working industry, and for the past 70 years has been developing customized solutions to effectively withstand heavy loads and dirty environments. Our equipment is built tough to perform reliably day after day operations and interface with front-end computer controls within automated systems and metal working equipment.

Experience & Expertise

Typical custom equipment solutions for the Metal Working Industry include:

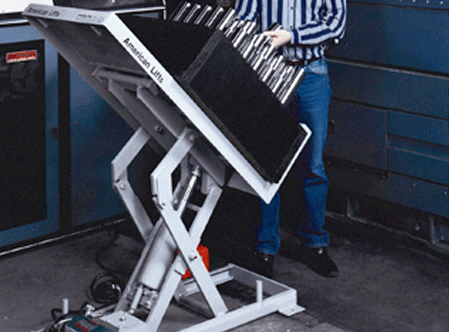

Surface-mounted lift and turn combinations allow operator to ergonomically and efficiently load aluminum castings onto a pallet.

Special scissor lift table with manual, mechanical actuation raises metal parts of varying sizes to exact heights before pushing the lift and parts into an oven for heat treatment.

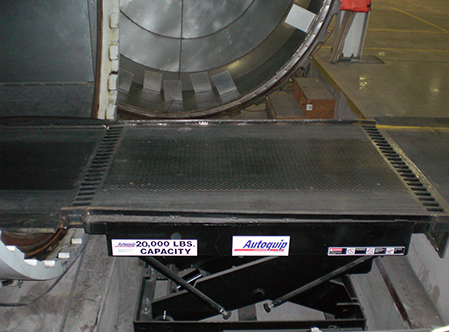

A heavy-duty high-travel scissor lift is used in handling and transferring extremely large molds in an aluminum processing factory.

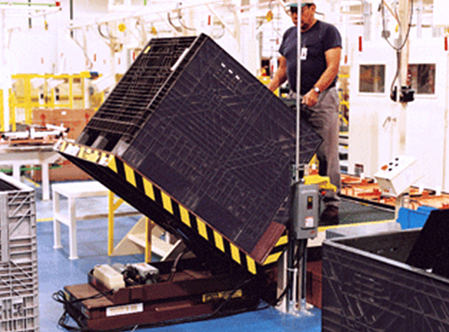

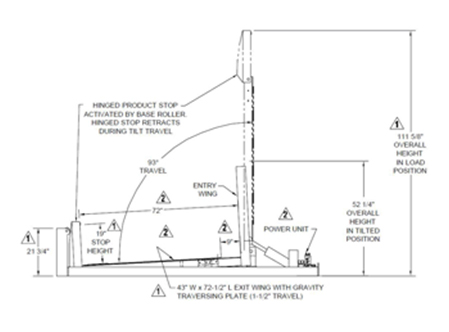

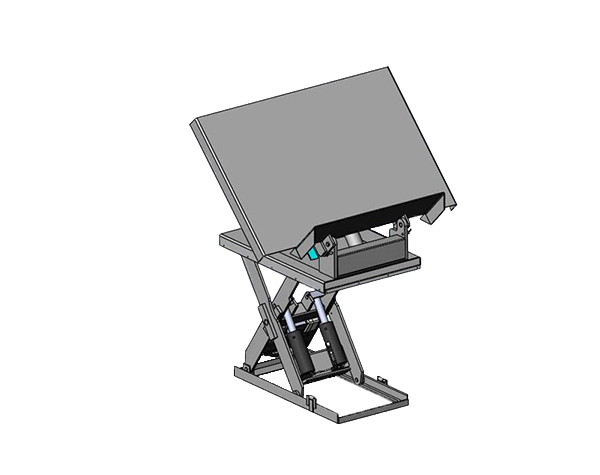

A special 90-degree tilter is used to receive coils from an overhead crane, then upend them from their sides to an upright position on pallets.

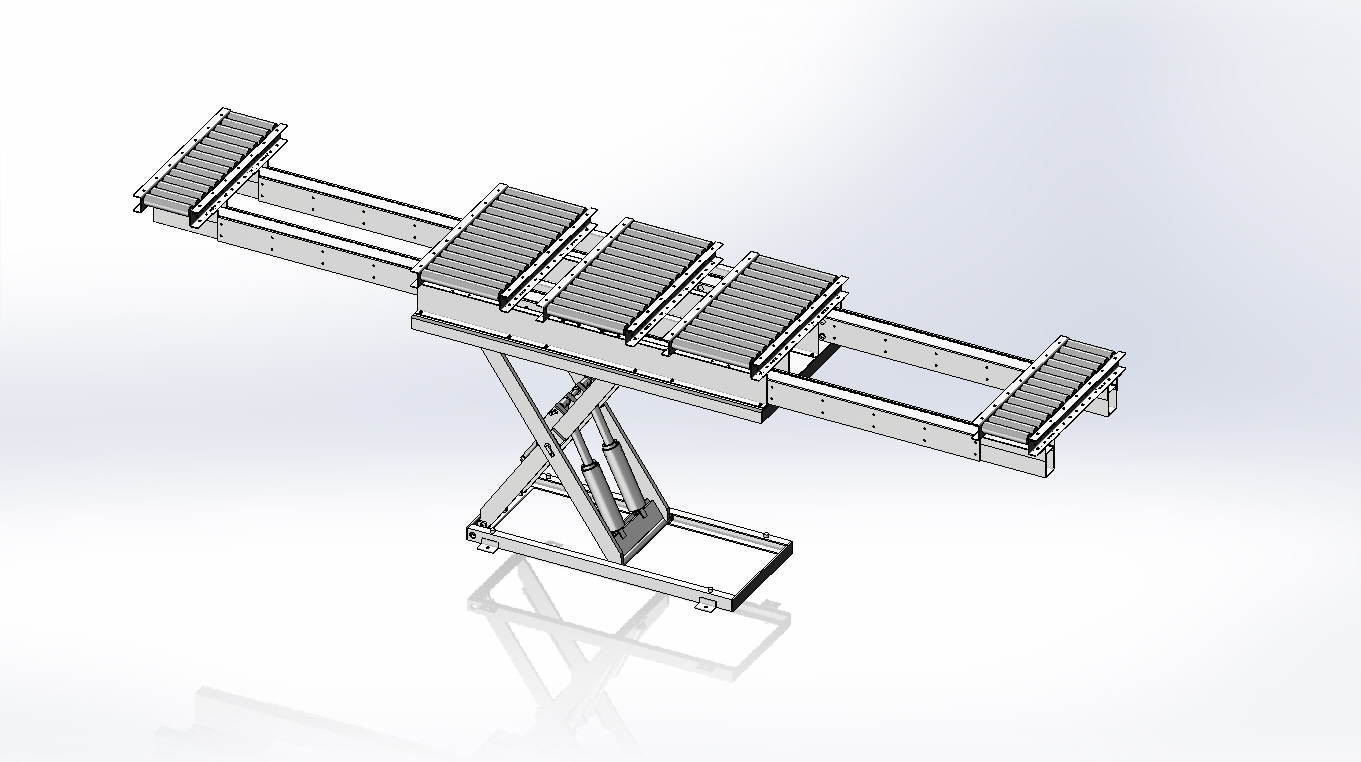

A high-capacity scissor lift on a traversing base has a large powered turntable for receiving, rotating, delivering/traversing, and raising sheets of metal to feed a blanking machine.

Scissor tables index up automatically as layers of sheet metal are pulled from the lift on the in-feed side of a forming operation.