Industries

Woodworking

Autoquip understands the unique demands of the woodworking and millwork industries to provide top quality product and craftsmanship. We have a comprehensive line of scissor lift tables, industrial tilters, and industrial turntables to improve every facet of operation. Our lift equipment enhances worker productivity and safety through ergonomics, increases efficiency and throughput by integrating with conveyor and automated systems to advance the production of wood products.

Experience & Expertise

Typical custom equipment solutions for the Woodworking Industry include:

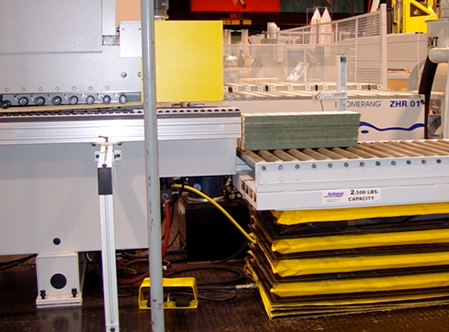

Hydraulic scissor tables equipped with photo-electric sensors are placed at either in-feed or out-feed conveyor positions adjacent to process machinery.

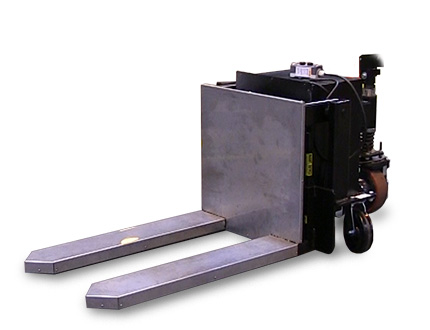

Foot-operated lifts installed just upstream of powered saws manually adjust the elevation of the top layer of lumber for ease of pulling and aligning the pieces into the saw.

Large footprint scissor lifts are used in stacking, de-stacking, and assembly of wooden doors.

Pneumatic and hydraulic lifts are used to keep assembly work ergonomically positioned in a stationary or conveyed production line to minimize bending and reaching.

Hydraulic or pneumatic scissor tables are used to ergonomically position cabinet components and assemblies with or without conveyor.

Foot-operated lifts are installed just upstream of powered planers to manually adjust the elevation of the top layer of lumber and plywood for ease of pulling and aligning the pieces into the planer.

Autoquip Clients

We have worked with some amazing teams.