Mobile Lift for Crop-Growers

Introduction

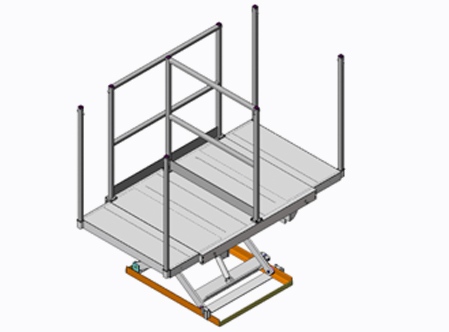

Mobile lift to automate the tasks associated with accessing fruit trees and bringing crops to market.

Project Challenge

Our customer requested a work platform that could be used as part of an overall design of mobile agricultural equipment designed to minimize the human interface. As with all such endeavors, the overarching challenge is to maximize the use of automation & technology without pricing the final product beyond the reach of most potential buyers.

Specific design challenges presented to the Autoquip design team during the definition phase of this product development: 1) Must be battery powered – utilizing the on-board 48VDC total power supply 2) Must be able to be easily mounted to, and removed from, a vehicle chassis 3) Must be as lightweight as possible for the lifting capacity required (two people) 4) Must have two (2) manually operated “shuttle” extensions which telescope out from the main work platform 5) Must be able to hold a particular elevation for extended periods of time without drifting down 6) Actuation must be able to be programmed using computer software/logic 7) Can not have system fluids that could contaminate the fruit being processed.

Our Solution

The most cost-effective designs that met the majority of the design requirements were hydraulically actuated lifts. However, the customer was adamant about avoiding drift & not using industrial fluids. That being the case, Autoquip recommended a linear-actuated mechanical scissor lift solution. This low capacity, custom lift utilizes a linear actuator in the scissor mechanism in the place where a hydraulic cylinder normally mounts, can be easily programmed, uses DC power, doesn’t drift down over time, and does not require industrial fluids under high pressure. A linear-actuated mechanical lift also made sense due to the low number of cycles that the lift would experience, and because the operating speeds were relatively low.

The Results

Customer was extremely satisfied with a cost-effective, mechanical lifting solution that provided a stable lifting structure with programmable and leak-free actuation, and the flexibility in design and performance to be adaptable to several crop-gathering and distribution tasks. As Nicole Dyer wrote for Popular Science on this equipment design in August of 2009: “Old MacDonald, meet the 21st century.”