Applications

Mezzanine

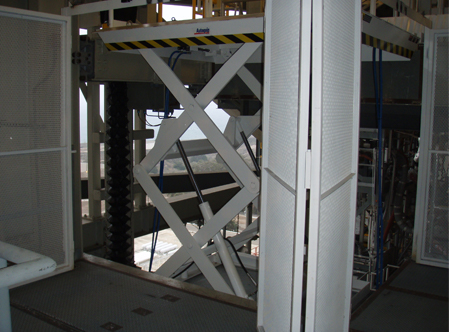

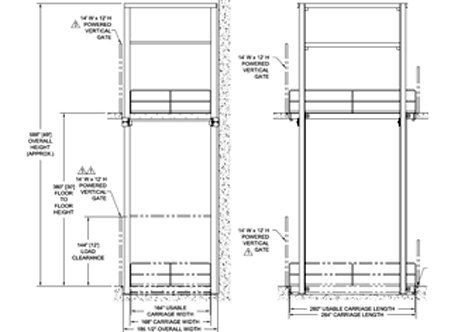

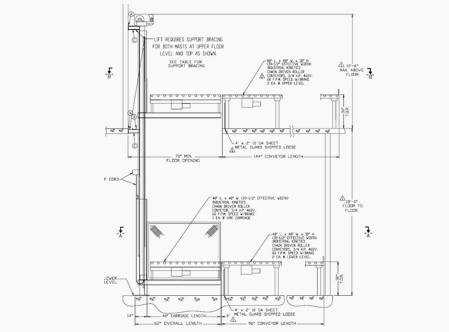

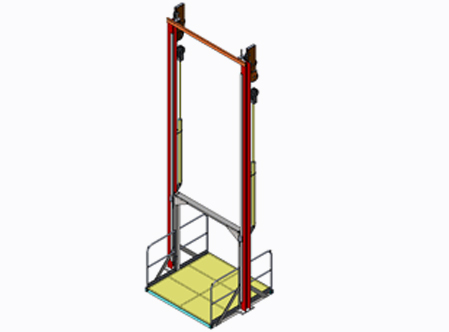

Autoquip is a world-class provider of scissor lifts, freight lifts, and vertical ram lifts for industrial mezzanine applications. This includes accessing multiple mezzanine landings with equipment and supplies, and expanding overhead storage space to increase the usable square footage of a building.

Experience & Expertise

Lifting and handling solutions Autoquip designed and manufactured for mezzanine applications include:

Vertical ram lifts used to vertically transfer loads of scenery between mezzanine storage level and stage level.

Hydraulic VRC lifts are used to transfer pallets of merchandise from ground level to a storage mezzanine.

A hydraulic VRC lift is used to store bulk product on a mezzanine at an automotive parts store.

Double-stacked scissor lifts are loaded by a fork truck at lower levels and transfers pallets of office supplies to cubicles and offices located on a mezzanine level.

Low-capacity, high-travel mechanical lifts are used to move small unit loads vertically between floor and mezzanine.

Mechanical VRC is used to access four levels in a building, allowing the transfer of tool boxes and equipment from the maintenance department in the basement to each level.