Applications

Pallet Handling

By improving the fit between the demands of palletizing/de-palletizing work tasks and the capabilities of the workers, Autoquip’s material handling solutions have benefited companies by reducing and/or preventing worker fatigue and injury, improving worker productivity and quality, and lowering worker's compensation claims and insurance costs.

Experience & Expertise

Lifting and handling solutions Autoquip designed and manufactured for pallet applications include:

Scissor lifts with a gravity conveyor or powered conveyor can both transfer and position pallets with product during the assembly and/or packaging process.

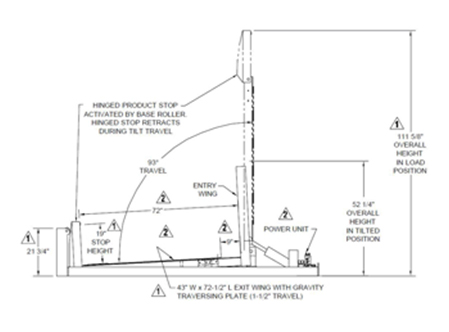

Special 80-degree tilters, used by a brush trimmer manufacturer, allows employees to build high stacks of lightweight boxes while standing on the floor, then tilt the stack up onto a pallet for shrink wrapping.

Industrial scissor tables with manual or powered turntables are used to build up layers of finished product onto pallets for shrink-wrapping.

These are hydraulic scissor tables equipped with photo-electric sensors, which are placed at either in-feed or out-feed conveyor positions adjacent to process machinery, automatically indexing up or down as layers of material are removed or added to a conveyed pallet.

Foot-operated lifts, installed just upstream of powered saws, manually adjust the elevation of the top layer of lumber for ease of pulling and aligning the pieces into the saw.

Industrial 90-degree tilters are used to down-end a palletized stack of layered goods, lay the stack on its side, and remove or replace damaged product within the stack before upending the load back onto the pallet for shrink wrapping.